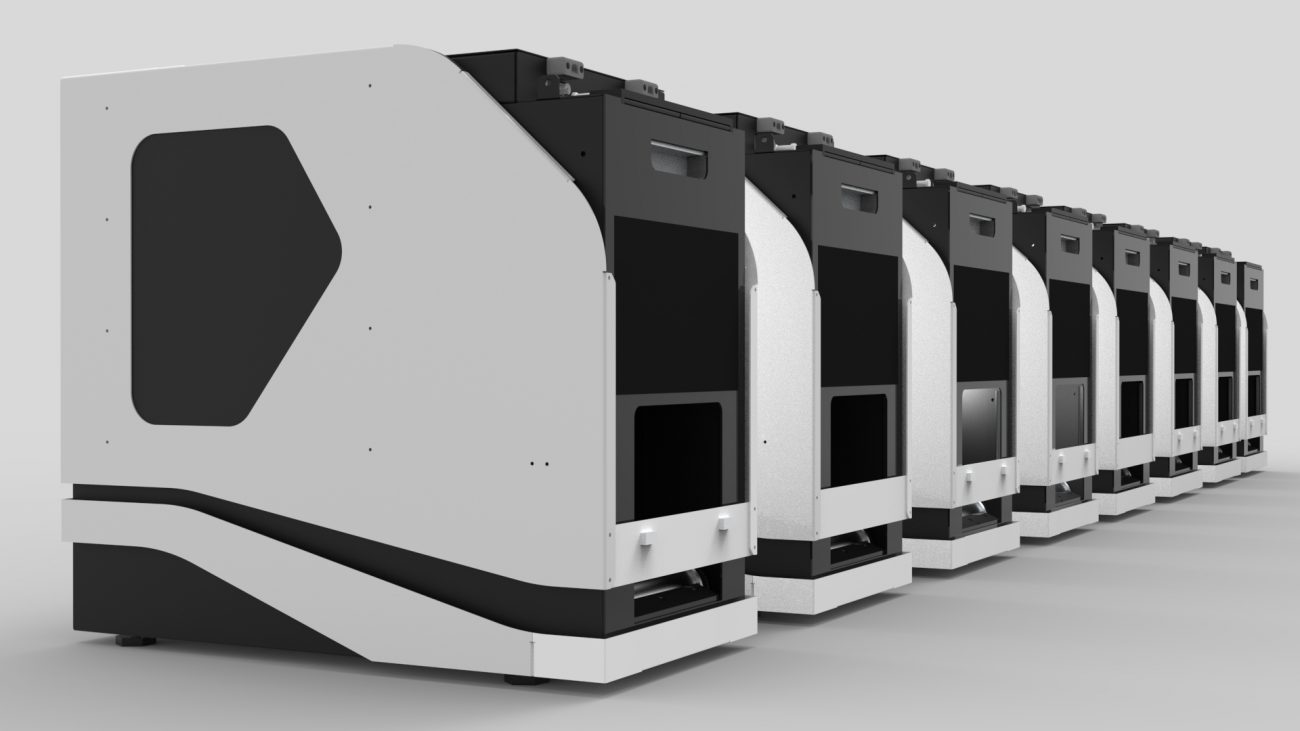

Insole 3D Printer

At Unityware Solutions, we specialize in developing cutting-edge manufacturing solutions for the medical industry. Unityware Solutions engineered a high-speed, low-maintenance 3D printer specifically for T-Soles in Netherlands, tailored to streamline custom orthotic insole production. The solution combines automation, precision, and cost-effectiveness—and is now being brought to market by T-Soles.

Smart Software & User-Friendly Interface

Our integrated medical insole design software enables seamless patient data import, automated slicing, and optimized printing workflows. A touchscreen interface ensures simple operation for clinicians and technicians.

Reliable, Cost-Effective Manufacturing

We reduced maintenance by 90%, engineered a high-durability system, and optimized manufacturing costs, maximizing profitability for our client while ensuring scalable production.

Outcome

Unityware Solutions designed a fully automated 3D printing system with a rolling belt mechanism for 24/7 operation, eliminating manual bed preparation. We increased printing speed while maintaining surface quality, enabled seamless soft material printing, and reduced maintenance by 90%. Our cost-optimized design lowered manufacturing expenses, maximizing profitability for our client.

Challenge

Traditional insole manufacturing requires manual supervision, slow production speeds, and frequent maintenance, increasing labor costs and downtime. Existing solutions also struggle with printing soft materials and maintaining cost efficiency for large-scale production.